Titan Enterprises Analyses Solutions for Low Flow Liquid Measurement

The measurement of low flow is becoming widely used in many industries. However, the smaller the flow, the trickier it is to control and measure, and finding a suitable flow measuring technology at reasonable cost can prove challenging for both users and flow sensor manufacturers.

There is no set definition for ‘low flow’ in terms of measurement limits for fluidics handling. However, low-flow applications encounter amplified flow stability and performance issues not seen in larger flows. The minimal liquid volume being measured in low flows renders them highly sensitive, such that even the slightest disruptions in process or ambient conditions can exert a substantial impact on flow stability.

Within the markets Titan Enterprises operates in, we consider low flow rates as those below 50 ml/min, with many customers seeking flow rates of between 2 and 20 ml/min.

Neil Hannay, Titan’s Senior R&D Engineer observes: “We are certainly seeing an increase in demand for low flow measurement technologies driven by various industries moving towards transporting heavily concentrated liquids, which are then diluted at the point of use. This translates into huge savings on transport and storage costs and also has a positive environmental impact.”

Whether cleaning fluid additives, syrups and flavourings for beer or soda, chemical additives for oil and fuel, paint pigments or administering drugs, low flow flowmeters are required to dose these concentrated fluids at the end process, dispensing the precise amount of liquid to the correct dilution.

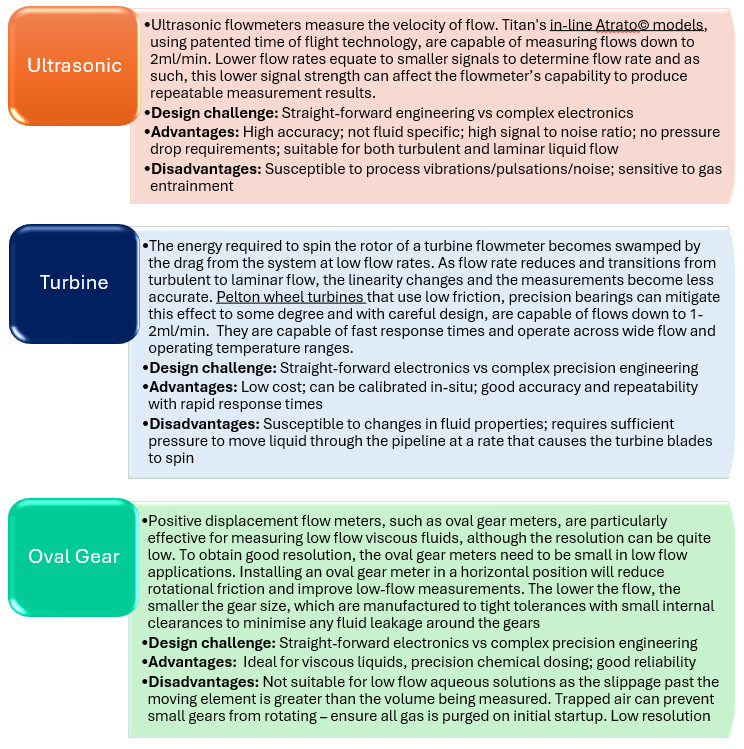

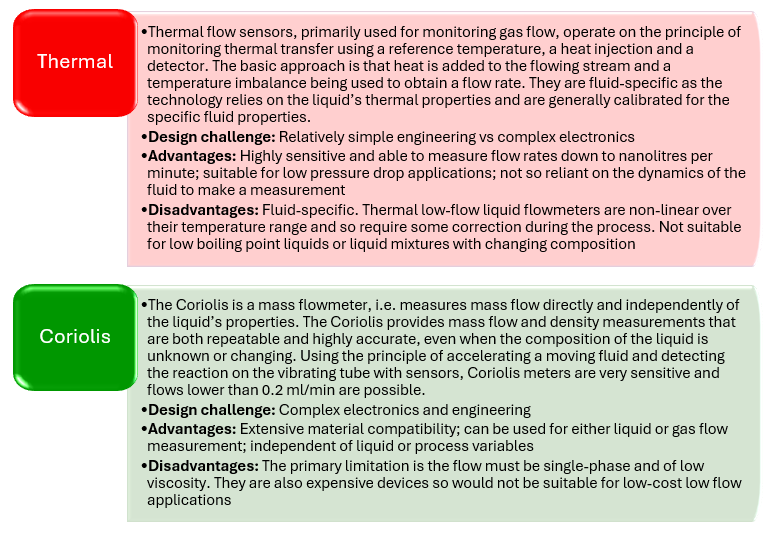

As mentioned, measuring low flow is a challenging application to satisfy. The amount of energy available in low liquid flow is unlikely to be sufficient to drive most mechanical flowmeters to give linear results. By comparison, electronic flow meters can be limited by sensitivity, zero drift and slow response times. Here we analyse 5 types of flow meter - Ultrasonic, Turbine, Oval Gear, Thermal and Coriolis - and their suitability for low flow measurement:

As flowmeters can be the most limiting component of a low flow fluidic system, it is essential to choose the most suitable high-precision flow sensor for your application.

“We know there is a strong market for low flow meters and we are currently working with two international OEMs to develop a solution for measuring ultra-low flows using our oval gear technology and miniaturised gears,” says Neil.

Visit Titan Enterprises’ website for further information on low flow measurement or to discuss specific technical applications, please contact Titan Enterprises on +44 (0)1935 812790 or email sales@flowmeters.co.uk.